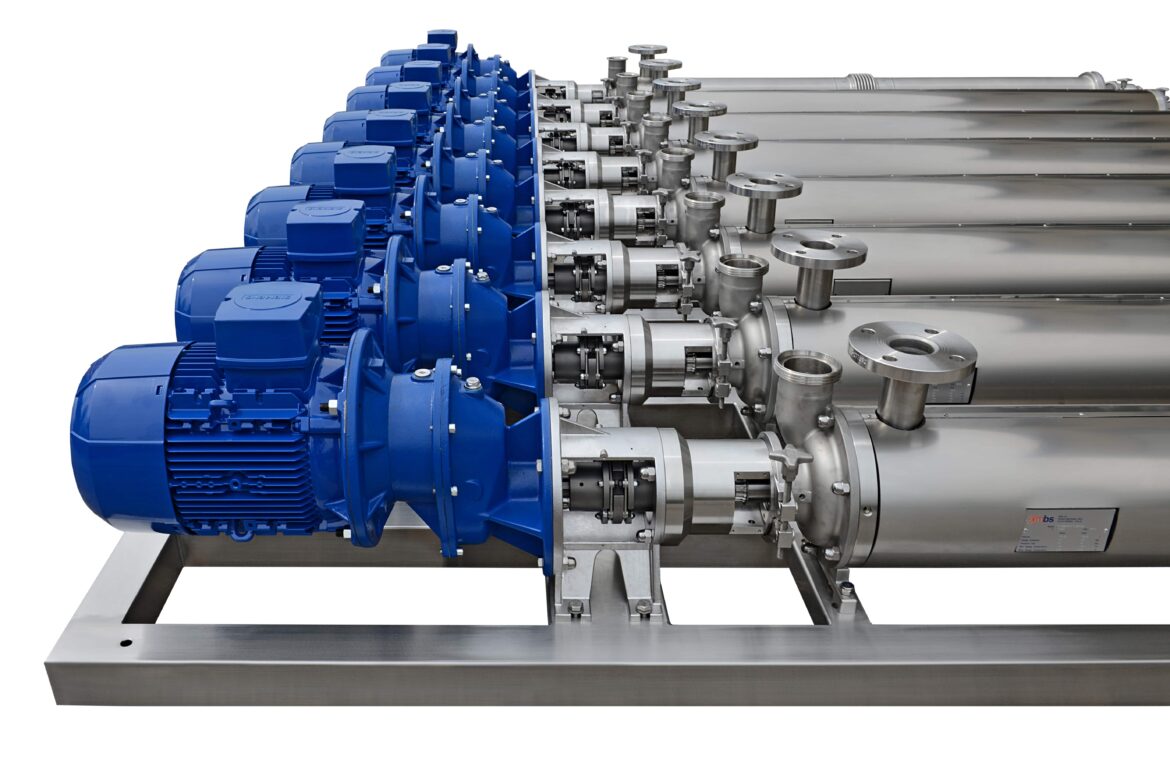

For nearly 30 years, MBS-a Parma-based company that has been producing heat exchangers for a wide variety of segments of the food and beverage and pharmaceutical industries since 1995-has been producing heat exchangers valued by manufacturing companies operating primarily in the food & beverage and pharmaceutical sectors.

“MBS solutions are the result of years of studies in the field of heat exchange conducted in collaboration with prestigious Italian universities,” the company explained in a recent statement. “Innovative, reliable and certified by important independent bodies, MBS products are made in full compliance with the stringent quality requirements of the sectors in which they are used. This is why the company uses excellent raw materials and components: including Mayr joints.”

We talked about this with Diego Reginato, head of MBS’s purchasing department.

Heat exchange at the center (and also at the sides)

Central to MBS’s business is the manufacture of shell and tube heat exchangers, whose excellent performance comes from in-depth studies carried out in collaboration with some of Italy’s leading universities on the effect of tube corrugation in heat exchange.

Diego Reginato

In the food and pharmaceutical industries, tubular heat exchangers are the choice of choice to achieve thermal energy exchange between two fluids without mixing them. Their operation is simple: the substance to be processed passes through one tube, while in another tube coaxial to the first, generally in the opposite direction, passes the fluid intended to heat or cool it.

In a normal exchanger it can happen that the exchange is not perfectly homogeneous, since the part in contact with the walls of the tube heats or cools more than the part in the center. In some cases this can be a problem: some fluids may get too hot and stick to the walls, while the part in the center remains at a lower temperature than desired.

To overcome this, MBS has developed a special type of scraped-wall heat exchangers called HERCULES. These contain rotating elements that skim the walls of the pipe, stirring the fluid being processed so that its temperature is uniform and preventing it from sticking to the walls.

Components at the height

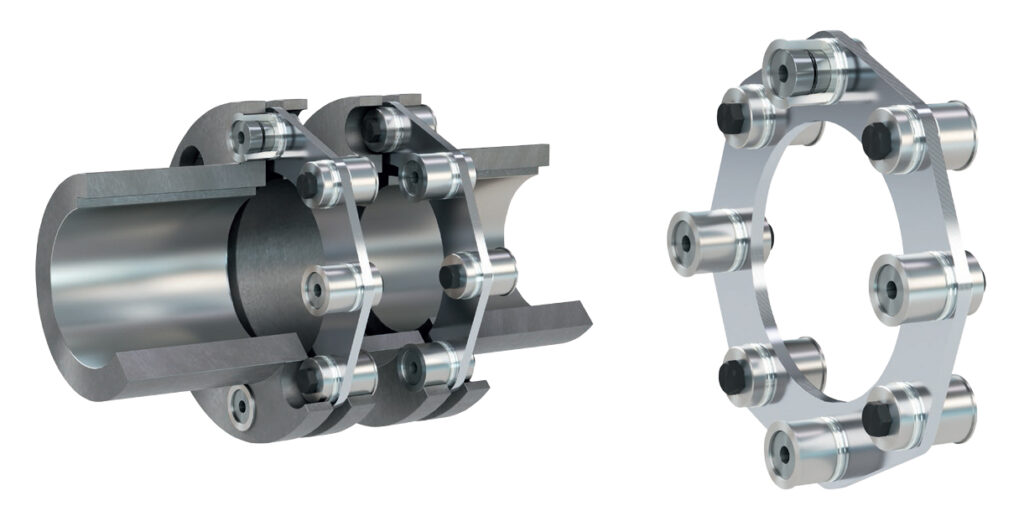

The rotation of the blades is made possible by a motor that transmits the rotary motion to the blades via a transmission joint. To ensure the continuity and uniformity of the production process, the transmission of the movement must be precise, uniform and constant over time.Therefore, it is essential to use a joint that is reliable, maintenance-free, capable of operating at the temperatures required by the process and that can if necessary be sanitized with the appropriate detergents to maintain the hygienic standards required in the area of use.

Where to find a component with these characteristics? Diego Reginato, who has been part of the MBS staff for almost twenty years, where he oversees purchasing and production planning, had no doubts: “Ever since HERCULES was to all intents and purposes still a mere prototype, we turned to Mayr for the supply of the joint, a company whose expertise and reliability we had come to appreciate: values that therefore overlapped with our own. The supplier worked alongside us to find an appropriate technical solution that could meet all the requirements of our application.”

Within the Mayr catalog, sales engineers identified the ROBA-DS joint as an ideal component for the HERCULES exchanger.

Robust and precise

ROBA-DS is a torsionally rigid and completely backlash-free steel lamellar joint that is among the most valued in the industry for its strength and precision.

Ideal for situations where maintenance needs to be zeroed out to ensure constant plant operation, ROBA-DS is perfect for HERCULES exchangers, used in industries where reliability is critical and any downtime would be particularly costly.

Design and construction features of ROBA-DS make it suitable for operation over a wide range of temperatures; the stainless steel structure is designed to withstand aggressive detergents used to maintain high levels of hygiene, such as in the food industry.

A heralded success

For MBS, HERCULES turned out to be a winner: designed to perfectly meet the needs of the target sectors, meeting stringent criteria for reliability, efficiency and precision, and manufactured by carefully selecting the best in terms of raw materials and components, the exchanger immediately seemed destined for considerable success, which punctually arrived.

“Since 2011 when we introduced HERCULES to the market, to date, almost 500 machines have been sold: really important numbers for our production,” Reginato explains, ” configurable and available with various options, it has been able to win over the most important companies in the food and pharmaceutical sectors with its reliability.

Ideal partnership

It was not only the excellent performance of the ROBA-DS joint that won MBS over: the technical features of the component were matched by impeccable service from the supplier.

“Mayr has proven to be absolutely reliable over time, maintaining consistently high production standards and on-time delivery; in addition to the feedback from the quality aspect, we can therefore confirm satisfaction with the professional relationship on our part and that of our customers,” Reginato concludes.

MBS thus joins a number of leading companies in their field that have found in Mayr a reliable partner, ready to work to meet every need in power transmission and motion control.