Tosaf’s light-diffusing masterbatches ensure uniform illumination even with LED spotlights. © Tosaf Color Service

August 2023 – At Fakuma 2023, Tosaf will be presenting their latest developments in masterbatches for applications ranging from agricultural films to rigid and soft packaging and technical parts on stand B4-4402 in hall B4. For example, Tosaf’s new additives for contour-sharp laser marking are also suitable for transparent plastics in a wide range of applications. Also in focus are a new masterbatch carrier system with approval for direct food contact as well as masterbatches to produce light-diffusing elements, for example for covers of LED lights. Adapted to growing sustainability requirements are blowing agents for foamed plastics that help to reduce the ecological footprint, as well as colour and functional masterbatch solutions for compounds containing recycled materials.

Contour sharp marking with the laser beam

Even small amounts of masterbatch cause

efficient light scattering in originally

transparent polycarbonate.

© Tosaf Color Service

A new laser additive family from Tosaf can be used for transparent applications without affecting the optical properties. It enables contour-sharp, high-contrast markings on thermoplastics that originally show poor or no colour change during laser marking, as well as on compounds with fillers such as calcium carbonate, talcum, titanium dioxide or carbon black. Depending on the substrate, optional settings for marking colours ranging from white to grey to black are possible. Since very low dosages are sufficient and the laser marking process can be fully automated, the new masterbatches help to reduce production costs compared to conventional processes such as labelling or embossing. By eliminating the need for chemicals, varnishes or stickers, their use is also non-critical and more sustainable. Typical applications include pipes, fittings, profiles and irrigation systems as well as, thanks to their suitability for food contact, caps and closures for beverages and other food packaging. Customised combi-masterbatches are also possible.

Food compliant masterbatch carrier system

A new universally applicable masterbatch carrier system from Tosaf Color Service meets all common food contact requirements, including those in Germany, the USA and China. Masterbatches based on this carrier system can thus be used without hesitation across continents for applications ranging from translucent and opaque materials for rigid and flexible packaging, toys and household items to components for food processing machinery and equipment.

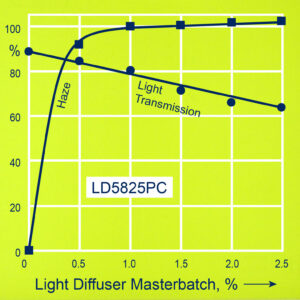

Light diffusing Masterbatches

To achieve uniform light distribution even with point-shaped LED light sources, Tosaf Color Service has developed light diffusing (LD) masterbatches that contain microfillers. Even very small amounts in the range of 1 to 2 % result in highly efficient scattering of light in originally transparent material, mainly polymethyl methacrylate (PMMA) and polycarbonate (PC). The light transmission and mechanical properties of the base material are almost completely retained. Both colour-neutral grades and combinations with specific colours and functional additives such as UV stabilisers are available.

Sustainability in mind

In the spirit of the circular economy, Tosaf has developed colour masterbatches specifically for recyclates, with a focus on post-consumer plastics. They compensate for origin-related inconsistencies that are typical for such materials. A special additive masterbatch range from Tosaf is based on biodegradable carriers such as polylactic acid (PLA) and resin (rosin) and gives corresponding agricultural films properties such as increased UV stability, anti-fogging and IR filtering.

Also geared towards sustainability in plastics processing are chemically active blowing agents that Tosaf has developed for the material-saving foaming process. The portfolio includes endothermic and exothermic types for a wide range of thermoplastics. Endothermic grades are considered safe to use, are approved for food contact and generally require relatively low temperatures for activation. Their applications range from thin-walled films and moulded parts with high surface quality as well as PP tapes to XPS and XPE trays for food packaging and large and thick-walled parts. The exothermic grades combine a high foaming effect with very good dispersibility. Exothermic and endothermic blowing agents combined in one concentrate are particularly suitable for PVC applications such as sheets, profiles and pipes.

Beyond colour and foaming agents, Tosaf’s portfolio includes other additives that can contribute to greater sustainability, including antioxidants, moisture and odor absorbers, processing aids and chain extenders.

For over three decades, Tosaf (https://www.tosaf.com/) has been developing and manufacturing high-quality additives, compounds and color masterbatches for the plastics industry. With the aim of providing for its customers’ every need, it has continuously grown and developed its offering, production capacity, and global reach, becoming a truly close to the market, global organization. Servicing customers in over 50 countries in Europe, North America, South America, Asia and the Middle East, Tosaf has over 1400 employees spread throughout its production sites, warehouses, sales and distribution offices around the world.

Tosaf CEO Amos Megides established the company in Israel in 1986, and still stands at its head, leading and inspiring his team to always uphold the following three pillars: Exceptional service, the highest quality and continuous innovation. Tosaf’s major shareholders include: Megides Holdings Ltd. and the Ravago Group.